High-index optical fibers are specialty fibers engineered with a core refractive index that is intentionally higher than that of conventional single-mode transmission fibers. This is achieved by precisely controlling dopant profiles in the glass preform, most commonly with germanium or other index-raising materials. Due to this elevated refractive index, high-index fibers support tighter optical confinement, altered mode field diameters, and tailored numerical aperture characteristics compared to standard telecom fibers.

Read More

Topics:

optical fiber,

fiber optics,

high-index optical fiber

For many fiber optic training instructors, frequent travel is a necessity for conducting classes at different sites, including universities, learning centers, and client facilities. To teach students to effectively use test devices like OTDRs and optical power meters, spools of optical fiber are required for replicating real-world fiber spans. However, this requires instructors to transport and manage multiple reels of optical fiber, along with other essential components. While this fiber is crucial for demonstrating concepts and hands-on testing, traveling with these spools can be a major source of frustration for instructors.

Read More

Topics:

optical fiber,

fiber optic training,

otdr training,

fiber network simulators

The holiday season is synonymous with vibrant light displays that captivate and enchant. A pivotal technology behind many of these dazzling decorations is optical fiber. From intricate ornaments to large-scale light shows, fiber optics plays a role in making the season bright.

Read More

Topics:

optical fiber,

fiber optics

As the world gears up for the 2024 Paris Olympic and Paralympic Games, the role of technology in delivering a seamless and immersive experience for millions of spectators and participants is more critical than ever. Among the myriad technologies being deployed, optical fiber stands out as a backbone of connectivity, ensuring everything from real-time broadcasting to robust communication networks.

Read More

Topics:

optical fiber,

fiber optic cable,

fiber optics,

2024 Paris Olympics

Along with Artificial Intelligence (AI), currently a very popular topic of discussion, Quantum Computing is another rapidly growing technology arena that represents a revolutionary leap in computational technology. Unlike traditional computing, which uses bits to represent data as 0s or 1s, quantum computing systems leverage the principles of quantum mechanics to process information in fundamentally new ways using quantum bits or qubits. Without going too deep into the details, qubits can exist in multiple states simultaneously due to the phenomena of superposition and entanglement, enabling quantum computers to solve complex problems at much faster rates than previous computing systems.

Read More

Topics:

optical fiber,

network simulation,

latency,

quantum computing

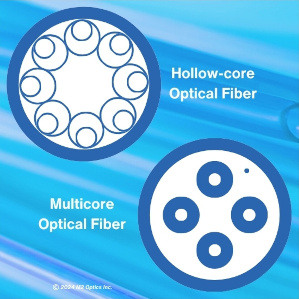

Serving as the backbone for many of today’s essential high-speed communications applications, optical fiber has been one of the most important technological advancements of the modern world. From supporting internet connectivity for people and businesses to connecting industrial automation systems, optical fiber enables the transmission of vast amounts of data for services we rely on daily.

Read More

Topics:

optical fiber,

hollow-core optical fiber,

fiber optic networks,

multicore optical fiber

An introduction to SDM and multicore optical fibers, an emerging area of technological advancement in the communications market.

Read More

Topics:

optical fiber,

fiber optic networks,

space division multiplexing,

multicore optical fiber

For universities and research institutions developing, evaluating, and testing fiber optic technology to advance global communications, using optical fibers to accurately simulate span performance and latency in the lab is often an essential step in projects. This brief article discusses how customized Fiber Lab solutions from M2 Optics help researchers and professors successfully address the precision, consistency, and protection challenges that arise when working with bare optical fibers.

Read More

Topics:

optical fiber,

network simulation,

latency,

universities and research

From supporting live online classes to delivering reliable high-speed internet services to students and administration, optical fiber networks play an essential role across university campuses. Discover the numerous benefits of implementing fiber monitoring systems and how they can enhance IT and communications services.

Read More

Topics:

fiber optic testing,

optical fiber,

fiber monitoring,

university campus