What are Polarization-Maintaining (PM) Optical Fibers?

Polarization-Maintaining (PM) optical fiber is a type of single-mode optical fiber designed to maintain the polarization state of light propagating through them. When light travels through a standard optical fiber, environmental factors like temperature changes, bending, and twisting can cause the polarization state of the light to drift or become random. For some applications, this is undesirable, leading to the design and development of PM fibers.

PM fibers use anisotropic structures to create different refractive indices for the two orthogonal polarization modes, a mechanism known as form birefringence. The birefringence characteristic enables the fiber to maintain the polarization state of the light over long distances and despite external influences. These specialty fibers are often used when preserving the polarization state is critical, including fiber optic lasers, gyroscopes, LIDAR, quantum key distribution, and medical applications.

What Role Does Polarization Play in Light Transmission?

In fiber optic communication systems, the role of polarization is significant, as it can directly impact the performance and reliability of the system. Light transmitted through an optical fiber consists of an electric field oscillating in two orthogonal polarization modes, commonly called the x and y polarizations.

Polarization plays a role in light transmission in fiber optic communications systems in several ways:

- Polarization mode dispersion (PMD): In single-mode fibers, the two orthogonal polarization modes ideally travel at the same speed. However, due to imperfections in the fiber's manufacturing, installation, or environmental factors, these modes can experience different propagation velocities. This differential delay between polarization modes can cause signal degradation, increasing bit error rates and reducing system performance. PMD becomes particularly problematic in high-speed, long-haul communication systems.

- Polarization-dependent loss (PDL): The attenuation or loss experienced by the light signal in an optical fiber can depend on the polarization state. This is due to the polarization-dependent properties of optical components, such as couplers, isolators, and filters, and can result in uneven power distribution between channels in wavelength-division multiplexing (WDM) systems.

- Polarization sensitivity of devices: Many fiber-optic devices, such as modulators, switches, and detectors, exhibit polarization sensitivity. Maintaining a stable and well-defined polarization state is crucial for optimal performance in these cases.

- Cross-polarization coupling: In multi-channel systems like WDM, the polarization state of one channel can couple to another, leading to crosstalk and impairing signal quality.

To address these challenges, fiber optic communication systems employ polarization-maintaining fibers and various polarization management techniques. These measures help to minimize the impact of polarization-related effects on system performance and ensure the reliable transmission of data over long distances and at high data rates.

Polarization-Maintaining Optical Fiber Applications

After addressing the role and importance of polarization in light transmission, let’s take a look at a few applications where PM fibers are utilized:

- Telecommunications: PM fibers are used in high-speed and long-haul communication systems to minimize polarization mode dispersion, which can degrade signal quality.

- Fiber optic sensors: PM fibers are used in sensors that rely on changes in the polarization state of light to measure physical quantities such as temperature, strain, and pressure.

- Fiber lasers and amplifiers: PM fibers are used in manufacturing fiber lasers and amplifiers to ensure stable output polarization, improving the performance and reliability of the devices.

- Interferometric systems: In systems like fiber optic gyroscopes (FOGs) and interferometers, PM fibers maintain light's polarization state, ensuring accurate, consistent, and stable measurements.

- Quantum communication: PM fibers are used in quantum communication systems, where preserving the polarization state of photons is crucial for secure information transmission.

- Remote sensing and LIDAR: PM fibers are used in LIDAR systems and other remote sensing applications that require precise polarization control for accurate measurements.

- Medical and biomedical imaging: In some optical coherence tomography (OCT) and other medical imaging systems, PM fibers are used to maintain the polarization state of light, improving image quality and resolution.

- Polarization-sensitive optical systems: PM fibers are employed in systems that require high polarization extinction ratios, such as in optical switches, modulators, and polarization-sensitive detectors

Polarization-Maintaining Fiber Design & Construction

PM fiber is designed to prevent cross-coupling between orthogonal polarization modes (which typically would lead to degradation in polarization fidelity) and this is achieved by inducing a significant difference in propagation constant (also known as birefringence) between the orthogonal polarization modes.

Standard optical communication fibers are made to be circularly symmetric so that any light polarization can propagate with minimal change. They are also designed to minimize birefringence rather than create it, thus they do not maintain polarization over long distances well. On the other hand, PM fibers are constructed differently to create a significant amount of birefringence. Two common PM fiber designs are PANDA fiber and Bow-Tie fiber which are highlighted below:

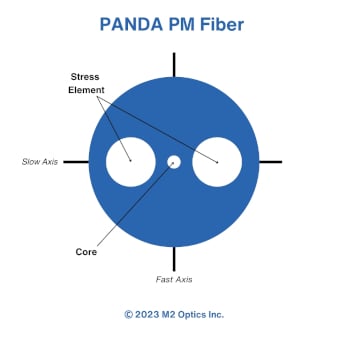

- PANDA PM Fiber – The PANDA design includes two silica stress rods on either side of the core. The stress rods are made from a different type of glass that reacts and expands differently under heat. When the fiber cools during manufacturing, the stress rods strain the core, causing the waveguide to be asymmetric. This induces a birefringence to help maintain the polarization of light propagating through the fiber.

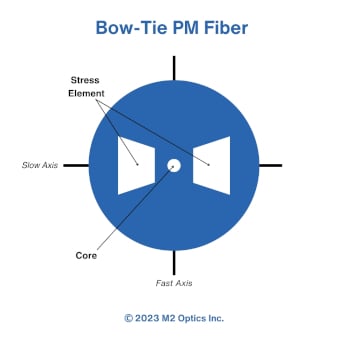

- Bow-Tie PM Fiber – The Bow-Tie design is aptly named for the bow-tie-shaped stress elements that are positioned on either side of the core, resulting in birefringence due to an asymmetric refractive index profile and maintaining the polarization of light in the fiber.

The shared design approach between the two fiber types, stress-applying elements, leads to two propagation modes – a slow axis and a fast axis. An optical light signal launched into one of these axes will then maintain its polarization state throughout the length of the fiber. As a result, when PM fibers are connected or spliced together, the process requires a careful and accurate alignment of their polarization axes, which is covered in the next section.

Splicing Polarization-Maintaining Optical Fibers

While PM fibers transmit light signals similarly to other single-core optical fibers, splicing this fiber is more complex than splicing other standard communications fibers due to the need to align the fiber's polarization axes. This process requires specialized splicing equipment and a careful approach.

Unlike standard fibers, PM fibers have specific polarization axes that must be aligned before splicing. This requires a splicing machine equipped with a polarized light source and a polarization state analyzer, along with the necessary capability to align the axes.

PM fiber splicing is a specialized skill that requires additional training and advanced expertise. The PM splicing device's significantly higher cost coupled with the process's complexity typically requires an experienced technician or engineer compared to performing standard fiber splicing.

Leading Polarization-Maintaining Optical Fiber Types & Brands

Numerous entities produce high-quality PM fibers, and the list includes the largest global optical fiber manufacturers and several leading specialty optical fiber manufacturers. A few of these PM fiber manufacturers include:

- Corning®

- OFS®

- Fujikura®

- Fibercore®

- Newport Corporation®

- Nufern®

- Thorlabs®

Polarization Maintaining (PM) Optical Fiber Solutions from M2 Optics

When PM optical fibers or components are required for testing and networking applications, M2 Optics offers several customized PM fiber solutions, manufactured for your specific engineering needs. Whether your project demands precision lengths of bare PM fibers in efficient rack chassis or modules for exactly simulating a proposed network span, or you require a 1xN PM splitter for a connectivity demand, M2 has you covered.

For more information, pricing, and technical specifications, contact M2 Optics or visit the PM optical fiber solutions pages below: