Often not considered, it is important to remember that looks really do matter!

For network equipment manufacturers, two necessary steps are a) testing their devices in the lab to ensure performance specifications and b) demonstrating the devices to potential customers when attempting to close a sale. While each may or may not happen at a different point in the process, both are extremely important and the outcome can ultimately determine a win or a loss against a competitor. What they share in common is that both involve utilizing spools of optical fiber to connect various devices in order to exactly simulate the intended field network.

While much effort and money is focused on the devices in these setups and rightfully so, often times the optical fiber that is being used to connect all the devices and simulate the physical network is overlooked. While engineers and lab managers know the fiber is an absolute necessity, not all take it a step further to think about how the look and organization of the fiber can have an impact on potential customers, company executives, and other related operational initiatives.

While performance of the setup will always be most important, it’s vital for equipment vendors today to understand that the look and organization of the fiber testbed does make an important impression on others, which can be positive or negative.

A Real-Life Scenario: Customer Visit for a Demonstration

As an example, let’s take a look at a scene that happens on a daily basis around the world. A large enterprise customer is considering purchasing an expensive network device from one of two possible vendors. Both vendors have invited the customer to visit their facilities in order to demonstrate their respective devices.

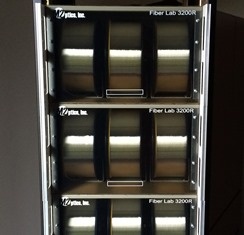

Upon arrival, the customer immediately notices the test fiber is setup in two vastly different ways:

|

|

Vendor A

|

|

Vendor B

|

So, what are some of the thoughts and questions that will almost certinaly come to the mind of the customer, simply from the looks of these two setups?

- Vendor A has invested more money and effort than Vendor B.

- Vendor A is more likely to achieve consistent, reliable performance results due to having a professional, organized setup.

- How can Vendor B identify the specific fiber types and lengths they are connecting to, when the spools aren’t easily accessible or identified?

- How does vendor B know that there aren’t issues with the fiber itself, given that the spools and leads are not secured?

- Why didn’t Vendor B put as much effort into building a quality test setup as Vendor A? If vendor B is cutting corners on the important fiber testbed, where else might they be cutting corners?

Any one of these thoughts going through the customer’s mind creates a negative perception about Vendor B, while likely instilling even more confidence in Vendor A as a result of the investment they have made in their fiber setup.

While the fiber testbed may not always be THE deciding factor in who they award their business to, the last thing a vendor wants in a highly competitive market is to invoke a negative perception about any phase of their business, or be viewed as a company that is not entirely up to par with the efforts of their primary competitors.

Additional Considerations

While it will require a slightly larger monetary investment up-front to build out a professional and organized fiber testbed, there are other benefits beyond customer visits and keeping up with the competition that engineers should always keep in mind:

- Protecting optical fiber appropriately saves money in the long-run, as it prevents damage that commonly occurs during handling.

- Organizing fiber in the most efficient manner not only saves valuable space, but it is virtually a necessity for those pursuing any level of test and connectivity automation.

- Organizing fiber also saves time when connecting fiber lengths, as well as eliminating having to search for specific fiber types or lengths in the available inventory.

- Engineers and lab managers take great pride in their work and department – maintaining a professional fiber testbed shows company executives that your team is doing everything possible to position your company for success.

- A great optical fiber setup makes life easier in general, for both engineers and technicians working with the equipment

As a company that has been focused on this particular area of expertise for over 15 years, this specific subject has become a more and more prevalent topic in recent years, especially as demands for advanced fiber-based equipment and the resulting competition between vendors continues to increase. In fact, we have had several instances where businesses have put just as much emphasis on the look of their setup as they have the performance to address many of the points mentioned.

The next time you require optical fiber and someone makes a statement along the lines of “let’s just buy some spools to save money,” it might be a good idea to share some of these best-practice considerations - the resulting numerous benefits have proven to always outweigh any short-term monetary differences.

-----------------

Contact M2 Optics for a Free Consultation

Since 2001, M2 Optics has specialized in helping businesses to get the most out of their optical fiber for network simulation, latency, and demonstration efforts. Whether you require new fiber, have existing fiber that you wish to organize in a more professional manner, or simply want to learn more about this topic, we are here to support you.

|

Free Whitepaper: |