Written by: Kyle Miller @ JEM Electronics, Inc.

In industrial systems design, such as robotics and telecommunications, the end result is all about pension and speed. As a design engineer, there are numerous paths of decision making when it comes to choosing between copper and glass fiber optics conductors. You hear the term “Fiber Optics” being tossed around a lot with telecommunications, cable TV, and the internet. Fiber optic cable is constructed of optically pure glass as thin as human hair. A downside to this high tech innovation has been that the optically pure glass core is fragile; it cannot be stretched or bent because the glass core can break very easily.

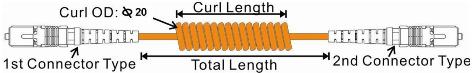

Coiled Fiber Assemblies overcome these issues, since when extending or bundling coiled fiber, you do not have to be concerned with compromising the quality of the cable. This results in substantial cost savings because you can buy one fiber cable to meet various length requirements.

Coiled Fiber is ideal for the following applications:

Military/Defense

- Adaptable length extension – Reduces the number of fiber cables needed in the field. One cable can be used in various applications that require different lengths.

- Solution to tight space requirements - Can be utilized in applications that have limited space. You have the benefit of flexible lengths while not having the issue of excess fiber cable. The coiled design neatly bundles any excess fiber cable.

- Durability – Coiled Fiber can be extended and recoiled without fiber glass breakage, extending the life of the fiber cable.

Datacenter/IT/IS and Medical

- Organization –Cuts down on wire clutter and keeps excess cables off the ground. Coiled Fiber not only helps with organization, but it also reduces safety hazards. The fiber is coiled up tightly rather than having the excess fiber hanging loosely, causing a potential safety risk.

- Fits well in very tight spaces – Coiled Fiber utilizes less space. This is an advantage when using the Coiled Fiber in an application that is short on space, or when storing the cable.

- Accommodates various cable length requirements – Less fiber cables need to be purchased. Furthermore, the problem of not having the correct length cable is reduced because one coiled fiber cable can meet various length requirements.

Robotics

- Flexibility – The coiled design is perfect for constantly moving parts that require fiber cables. The flexible length extension greatly reduces the problem of fiber glass breakage.

- Cost savings – Fiber Optics are expensive. Coiled Fiber can be stretched without breaking the fiber glass. This means less fiber cables will be replaced, which saves the time and money associated with replacing damaged cables.

- Long-lasting – The slinky-like design is rated for up to 80,000 stretches, which let’s your Coiled Fiber investment stretch even further.

For more information about coiled fiber products, click the picture below: