There's an old business saying, "If you are not innovating, you are dying." Similar to other industry sectors, the telecommunications and fiber optic technology arena is no different. In this rapidly growing and evolving landscape where network equipment manufacturers and service providers are racing to deliver ever-increasing amounts of data to satisfy global demands, staying ahead of the curve and the competition is more than just a business strategy - it's essential. No two networks are exactly alike and various challenges arise frequently that companies must be able to successfully navigate. Differentiation is a key element in a highly competitive market – those who can take new products and enhancements to market faster, find creative solutions to quickly overcome unexpected issues, and reduce supply lead times for clients are just a few examples of ways companies can gain a competitive advantage.

This is where 3D printing and 3D design services emerge as innovation game-changers, offering unparalleled benefits to fiber optic equipment manufacturers and service providers alike that can successfully leverage this technology. First, we will look at some of the ways 3D design and printing can benefit companies in the fiber optic technology space.

Benefits of 3D Printing and 3D Design for Telecom & Fiber Optic Communications

1. Faster and More Flexible Prototype Development

One of the most significant advantages of 3D printing is rapid prototyping. Instead of waiting weeks or often months for traditionally manufactured materials and the resulting prototypes, which becomes even longer when the process includes multiple design iterations, network equipment manufacturers can have finished prototypes in hand within days or even hours. This speed fosters a dynamic R&D environment, allowing quick development iterations and faster time-to-market for new equipment.

2. Value-Driven Customization and Production of Non-Standard Parts

Fiber optic and other types of telecommunication network equipment often demand the use of intricate, precision components. Additionally, situations arise where a customized, non-standard part is a better fit to achieve a specific engineering objective or solve a challenge. Instead of trying to make an available off-the-shelf standard part work or utilize traditional manufacturing methods and materials that can result in inefficiencies, expensive costs, and/or longer lead times to produce, 3D-designed and printed parts offer a better alternative that saves both time and money while maximizing results.

3. Improved Inventory & Supply Chain via On-Demand Manufacturing

For telecom network equipment manufacturers and service providers, stocking and managing materials and spare parts for a wide array of devices and systems often results in high costs and logistical challenges. 3D printing offers a solution by facilitating on-demand production. Instead of maintaining vast inventories, printed parts can be manufactured as or when needed with shorter lead times, reducing inventory material and warehousing costs, while reducing waste.

In recent years, global supply chains have been strained due to material shortages, production facility staffing challenges, and higher shipping costs to support large demands. By utilizing 3D printing and additive manufacturing technology, supply chain challenges can be greatly mitigated. Parts can be produced faster, sometimes eliminating complete elements of a traditional supply chain like materials suppliers, extra shipments, and other factors that contribute to longer lead times.

4. Supports Sustainable Manufacturing Efforts

The additive nature of 3D printing means less material waste, as parts, components, or complete products can be produced accurately, eliminating a lot of excess material (which also eliminates related costs of unusable excess material). As the telecom sector moves towards greener practices, adopting 3D printing into the business model can contribute significantly to sustainability goals.

3D Printing and 3D Design – Two Essential but Different Elements of Additive Manufacturing

3D printing and 3D design are integral facets of the additive manufacturing process, each a separate and necessary process, yet intimately interwoven in the journey from concept to a tangible product.

While the 3D printing process including the machines receives most of the press and attention, 3D design is the foundational process of transforming ideas into digital blueprints, requiring a sophisticated understanding of geometries, design intricacies, printing machines, and knowledge about the various types of materials and behaviors. Additionally, it requires a high degree of experience using related design tools and software to be able to create and produce design files efficiently and accurately.

As this technology has matured, the market has become flooded with numerous 3D printers and printing services, providing easy access to rapid prototyping and production at various scales. All you need to do is run a quick web search and you will likely find all types of machines available to purchase, covering the complete range from basic to advanced, along with many local 3D printing service companies.

However, the successful realization of intricate and complex 3D printed designs largely hinges on the expertise of seasoned 3D designers. These professionals possess the nuanced knowledge necessary to optimize designs for the printing process, ensuring both functionality and aesthetics. Given the specialized skills involved, far fewer advanced designers exist compared to the number of entities selling or providing access to the machines themselves. Companies seeking to leverage this technology must make a choice to either invest in the required machines and hire in-house designers or outsource one or both elements to a qualified 3D service provider.

It's important to note that many 3D companies focus their service offering on the printing aspect, requiring a design to be submitted, and do not always provide the 3D design service. When they do, engaging an experienced 3D designer or team can sometimes entail a premium, a result of their pivotal and important role in the process. When evaluating this entire process for a business or department, it’s beneficial to consider and develop a plan for both important facets of the additive manufacturing process, especially the design element.

The Advantages of Outsourcing 3D Design and 3D Printing

So as a telecom or fiber optic communications equipment manufacturer or service provider, you have decided to utilize additive manufacturing – great! As noted in the previous section, you must now determine the preferred approach: invest in the necessary equipment and people to perform 3D design and/or 3D printing in-house or outsource. Like any other business department, knowing the right equipment to buy for your application needs and hiring qualified staff can be an expensive and time-consuming venture, so outsourcing to a qualified third-party partner can offer several advantages:

- Maximizes Efficiency and Cost Savings

Instead of spending excessive time and money hiring and training staff and acquiring and implementing a complete in-house 3D printing infrastructure (which also demands physical space occupancy), telecom and fiber optic businesses can tap into the expertise and equipment of specialized partners, converting fixed costs into variable ones. After selecting an appropriate 3D design and printing partner, they can be utilized as needed, resulting in significant cost and time savings. - Provides Access to 3D Technology Expertise

3D printing and design is an evolving field. By partnering with qualified experts, telecom and fiber optic businesses can leverage the latest technologies and design methodologies without needing to constantly upskill in-house teams.

Utilizing experienced 3D designers is critical and outsourcing provides access to this expertise without the costs associated with finding, hiring, and onboarding full-time team members. Today, many manufacturing and technology companies own 3D printing machines but still lack highly-skilled design staff or sometimes simply don’t want to commit time to creating designs in order to focus on their primary business objectives. Utilizing a 3D design partner, even just for that aspect of the process, results in tremendous benefits. The most qualified 3D designers stay updated on the latest trends, knowledge, and materials, and will know the most effective and efficient design approach as specific needs arise. - Eliminates 3D Printing Machine Maintenance

Like all machines, 3D printers and the environment in which they operate must be properly maintained on a continued basis and an array of issues can arise during the printing process. From outputs not printing as expected due to an underlying issue or machine parts needing replacement over time after regular or excessive use, to ensuring optimal environmental temperature and humidity values for ensuring "best print" conditions, 3D printing machine maintenance and expertise for quickly solving machine-based challenges that can arise is often overlooked. Having to hire a 3rd party entity to fix problems can be costly and time-consuming, especially if an issue occurs during a production effort when time constraints or a deadline is a factor. Outsourcing eliminates having to deal with these challenges entirely, as a qualified 3D printing partner will have the necessary means to effectively manage machine maintenance and issues. - Enables Scalability, Increases or Decreases

As demand fluctuates, utilizing a reliable third-party 3D technology partner ensures that design and production can be scaled up or down seamlessly, without the hassles of managing an in-house facility, including both the equipment and staff. When demand increases, new designs and parts manufacturing can be scaled up accordingly in collaboration with the partner. Alternatively, if things aren't going as planned or the market enters a downturn, processes can be scaled down without a lot of tough decisions or staff changes until things turn around again.

M2 Optics – Your Trusted 3D Design and 3D Printing Partner for Telecom / Fiber Optics

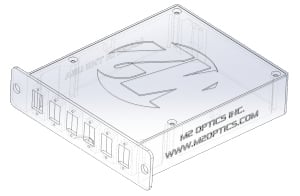

While recognized globally for delivering customized optical fiber solutions for testing and latency-driven networking applications, M2 Optics offers 3D design and 3D printing services for all entities building,m installing, or maintaining telecom and fiber optic equipment. Providing instant access to a dedicated department of skilled, award-winning 3D design professionals and the latest 3D printing technology, M2 is your trusted partner for outsourcing your design and printing needs.

Why Choose M2 for 3D Design and 3D Printing Needs?

- Rapid Design & Prototyping - experienced 3D designers with vast industry and technology expertise

- Dedicated 3D Printing Department - multiple printer technology types and materials available

- Cost-effective & Timely Service - quick designs (often at no cost!) when M2 also produces the prototype or part

- 3D Technology Passion - we love the technology to help you achieve your design vision and goals

M2 has produced rapid prototypes for research and conceptual R&D testing, completely new and finished customized products and components for network equipment manufacturers in less than 24 hours to minimize supply chain lead times, and delivered non-standard parts to service providers for solving unexpected challenges in the field network.

No project is too small, big, or challenging - our goal is to help you innovate faster and win the fiber revolution!

Contact M2 or an authorized partner for your upcoming 3D design, 3D printing, or additive manufacturing needs today.