Interested in learning more about remote fiber test systems and how they work? Intended for those seeking a better understanding of solutions for successfully maintaining fiber optic networks, this article focuses on remote fiber testing systems, which are a valuable tool for network operations teams.

Fiber optic cables are critical for telecommunications, connecting cities and countries all across the world. As a result, they need to be tested regularly to ensure they maintain a good condition and continue to carry data without interruption or issue. Since it is not feasible to manually test every individual optical fiber since each cable may contain hundreds of fibers or are not always easily accessible, a remote fiber testing system can be used to effectively solve this challenge.

The optical fiber market is growing at a rapid pace, with the annual market growth expected to reach more than $34 billion by 2025.

Maintaining the fiber network is one of the biggest challenges faced by every service provider. A broken or degraded fiber cable is a common occurrence that negatively impacts uptime, customer satisfaction, service delivery, and the financial bottom line. While there are numerous aspects of a network that must be regularly maintained, including both hardware and software, the physical optical fiber infrastructure is critical - a broken or damaged fiber cable means that data will not reach its destination regardless of the other network components.

This overview explains everything you need to know about remote fiber testing systems – what they are, how they work, and how every service provider can benefit from utilizing them.

What Is a Remote Fiber Testing System?

A remote fiber testing system, commonly known as a fiber monitoring system, provides the most efficient solution for monitoring the integrity of fiber optic cables in a network. Given the vast number of optical fibers deployed in networks today and the time and cost it would take for humans to routinely and manually test each fiber, a remote fiber testing system allows for continuous and automated monitoring of fiber cables for breaks, degradations, and malicious tampering incidents.

Deploying a fiber monitoring system provides the advantage of continuous assurance of optimal service while alerting field technicians in real-time when issues arise to allow for faster repairs and issue resolution. Thus, it not only maximizes performance for the network users but also saves the service provider significant operational costs and time when they can identify and locate issues quickly.

Added benefits include the ability for service providers to identify trends and issue areas, along with tracking important fiber performance metrics over time.

How Does a Remote Fiber Testing System Work?

The Technology

While there are a number of manufacturers around the world that design and build these types of devices with varying degrees of capabilities and performance specifications, most systems utilize a similar technology approach.

To detect a physical issue or event that may arise in an optical fiber, these systems often include an OTDR. This is a device that sends a light pulse and evaluates the signal reflections for identifying light loss/attenuation events in an optical fiber, which can include serious issues like a break to simply the end of the cable. Thus, the OTDR is able to precisely determine where in a fiber the event(s) occur and provide that data to the user, making it a highly valuable tool. While most OTDRs are designed to be handheld units that fiber optic technicians carry as part of their testing toolkit, some are manufactured for use in systems like these.

The OTDR monitoring signal, while in some systems is adjustable, will be a light wavelength that is different from the wavelengths carrying data, so that the monitoring signal will not interfere with data transmission. As an example, many monitoring systems use a non-intrusive wavelength of 1625nm or 1650nm, since single-mode networks transmit data in the 1310nm to 1610nm range.

For fiber monitoring applications, the OTDR is typically paired with both management software, a 1xN optical switch, and some other components depending on the system. Additionally, some systems integrate everything into an all-in-one solution, while others combine separate modular pieces of hardware together. This grouping of technology provides the ability to test and monitor a number of connected fibers on a routine basis, then send alerts in real-time when an issue arises.

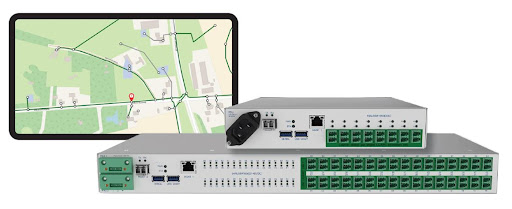

Once acquired by a service provider and connected to network fibers, the management software included allows the user to configure these units in a wide variety of ways, depending on their unique monitoring needs. In addition to setting the performance parameters of the OTDR, a user may be able to adjust things like system sensitivity, the types of alerts generated and who they are sent to, configurations for dark vs lit fibers or P2P vs PON fibers, and monitoring fibers at specific and/or periodic time intervals. Lastly, some systems include or integrate with 3rd party mapping software, helping to provide a visual representation of the monitored network and where an issue occurs to the benefit of the field technicians making repairs.

Fiber Monitoring Best Practice: When evaluating potential fiber monitoring systems for a network, it is always a good idea to determine the primary goals and objectives related to your needs, then evaluate multiple systems to determine which will deliver maximum benefit.

For example, do you need basic fiber monitoring capabilities to quickly identify issues or a more comprehensive fiber management platform that may include other non-fiber monitoring capabilities? Is available rack space an issue? Do you anticipate future network growth and require a system that will scale efficiently as more fibers are installed and activated? What level of vendor support is included with the system should you have questions after installation? Don’t hesitate to ask questions - a knowledgeable vendor or system provider should be able to answer your technology questions in a helpful and timely manner.

What Types of Issues Can You Detect With a Remote Fiber Testing System?

Fiber issues generally fall into one of just a few types of categories:

- Accidental (ex: a fiber is broken during a construction project)

- Malicious (ex: someone purposely cuts or tampers with a fiber)

- Random or uncontrollable environmental event (ex: earthquake)

Within these categories, remote fiber testing systems can help to detect a wide range of detrimental events, some of which are not always top of mind in terms of issues that can arise:

- Animals causing damage to cables and fiber strands

- Fire damage

- A hacker tapping a fiber attempting to steal data

- Downed telecom poles and fiber cables from storms, severe winds, or ice

- Submerged cables and network equipment during a flood

- Excessive bends or breaks during network installation or service connections

- Splices degrading over time or damaged accidentally during other handling and repairs

- Fibers spliced back together to incorrect fibers in a cable during repairs

- Hunters using aerial cables for target practice

In any of these instances, the damage may be minor or severe. For example, a cable may be crushed to a degree but not totally broken, and data still flows but with a high level of signal loss. Or, a fiber may be severed entirely, causing a complete outage.

In summary, the negative consequences of virtually any situation that service providers regularly face that results in a fiber being damaged or broken can be mitigated or even eliminated using active remote monitoring.

Primary Benefits of a Fiber Testing & Monitoring System

As we've mentioned, some of the biggest frustrations and challenges for service providers and network operators include broken fibers and degrading cables. Besides making it easier for technicians to find and repair issues, there are several benefits to using a remote fiber testing system.

Time Savings / Reduced MTTR

The "Mean Time to Repair" or MTTR, which is a standard way of measuring how long it takes to resolve an issue from the time it occurs until it is fixed, is an important metric to network operators. Without a way to accurately locate a physical fiber issue, simply finding the issue point can take 6-8 hours or sometimes even longer, depending on the complexity of the network and engaging the appropriate technician teams. The longer this portion of the process takes, the more money is spent in terms of labor hours, which can be even greater during nights, weekends, and holidays. Furthermore, the longer the MTTR, the more frustrating it is for users, so extended downtimes can result in a loss of customers and revenue.

By installing a remote fiber monitoring system, a network operator will be automatically notified in real-time when an issue occurs, along with receiving the precise location (down to a few meters) of the event. As a result, the MTTR can be reduced significantly along with related costs when repair crews can be dispatched directly to the right place, sometimes before the user even notices there is a problem.

Reduces or Eliminates Costly Repair Labor and Tasks

Each time a repair crew needs to be dispatched to a fiber break, the operational expense account increases. Industry estimates show that for most service providers, the cost of simply starting up and rolling out a truck to investigate a fiber event can cost between $100 and $500. For some large telco carriers, a single fiber break may involve rolling multiple trucks and crews, further multiplying these operational costs. For smaller network operators, they may rely on 3rd party contractors for truck rolls and repairs, which can be even more costly per instance. Considering this is before the added time and labor costs to travel to the location and resolve the issue, it is very expensive to repair fiber problems.

By installing and utilizing a fiber monitoring system, truck rolls are reduced or completely eliminated. Time spent finding the location of the issue is drastically minimized, saving large sums of money and labor hours on an annual basis, not to mention maximizing network uptime for users and customers.

Improved Performance Monitoring and Advanced Warnings

An installed fiber testing system can help to provide a level of performance monitoring in the sense that potential issues may be identified in advance of becoming a more serious issue. By routinely checking fibers, the system can spot increased signal loss in the fiber, like a degrading splice or where a fiber may have been mishandled or has become slightly crimped during other network maintenance. This allows a repair team to make the necessary repairs or improvements before it becomes a larger issue.

Establish Baseline Fiber Performance References

Because these systems typically start by taking a baseline measurement of any connected fiber and then monitor continuously against that baseline, it then provides an improved understanding of the expected performance for a given fiber. Once the baseline has been established along with other “known” elements in the fiber (splices, connection points, etc.), the network operator has a better sense of where performance should be on a regular basis. Furthermore, since most monitoring systems allow for the adjustment of sensitivity thresholds for alarms, if it turns out that too many false alarms are being generated against the initial baseline, the user can adjust the sensitivity to a more ideal setting that establishes a revised baseline taking into account these other false alarm-causing variables.

Identifying Frequent Problem Areas

Once monitoring network fibers via a regular test procedure, are specific cable segments or links experiencing more issues and alarms than others? Utilizing this type of system can help to better spot areas of the network that may be experiencing more issues than others, allowing the network operator to improve safeguards or shift repair team resources to better address recurring problem areas.

Who Should Use Remote Fiber Monitoring Systems?

It's hard to imagine a situation in which remote fiber monitoring would not be useful. Large telecom and data center enterprises that have thousands of fibers installed require more efficient solutions for determining where and when a break happens. Smaller companies that simply don't have the budget for a dedicated technical crew can install a remote monitoring system to make call-outs simpler and faster—simply knowing where and when breakages occur reduces the hourly cost you'll have to pay a contractor.

But what about cities and electric utilities?

With fiber serving as the backbone of virtually all communications networks, cities and utilities are similarly expected to maintain their networks and keep a high level of availability/uptime. The large areas typically covered by a single metro means that the list of environmental issues that can happen is vast. Additionally, critical communications infrastructure like 9-1-1 emergency services and electric utilities must be operational at all times, so for these types of services, availability is not just desirable; it is absolutely critical.

As investment in infrastructure grows at a state and local level, more and more emphasis will be placed on uptime and network performance.

A single unexpected event can have a disastrous impact on your network, whether a bad driver knocks down a pole, a squirrel chews through a cable, or someone maliciously tampers or attempts to cut communications. Resource expenses and OpEx grow rapidly when technicians are forced to waste hours of time across miles of fiber infrastructure to find a single break. With many municipalities operating under budget constraints, a fiber monitoring system is a small investment that will pay for itself very quickly.

Remote fiber monitoring is also important for rural applications. If you consider that most rural installations have less support and resources than their major city counterparts, fiber monitoring systems help to keep people connected while saving service providers time that would otherwise be spent on troubleshooting.

What to Look For When Purchasing a Remote Fiber Testing System

While still a fairly specialized type of device for a specific application, over the years a number of reputable equipment manufacturers have designed devices and continue to develop and improve fiber monitoring system technology. Like any product in the market, the systems offer varying degrees of features, performance capabilities, physical size, and cost implications.

From a user perspective, when shopping for a system, there are a few important factors that should be top of mind in terms of goals for the system itself:

- A small rack footprint

- Simple installation and setup

- Easy user management

- Accurate and effective fault detection

- Automatic, real-time alerts

- Quality technical support

- Any other “must-have” features

A Small Rack Footprint

Since fiber monitoring systems are typically deployed at multiple points in a network to effectively cover the intended fibers, there is often not an abundance of rack space available, especially when deployed in small remote network huts or pedestals. Additionally, while fiber monitoring systems save operational costs, they do not directly generate revenue and take rack space away from revenue-generating or other necessary gear. Thus, it makes sense to choose a highly efficient device in terms of the physical size and footprint, as not only is it easier to manage but it also leaves more rack space for other network equipment.

Many fiber monitoring systems were designed to be modular, which is beneficial for changing configurations, but more moving parts can also result in the increased risk of failures, costly upgrades to change entire portions of hardware, etc. Alternatively, “all-in-one” integrated devices are now available, which may lack the ability to change or upgrade a 1xN switch, for example, but less hardware often translates to significantly lower costs and improved space efficiency in terms of the footprint.

Simple Installation

The point of fiber monitoring is to save time and money, so it doesn’t make sense to acquire a system that is time-consuming or painful for a team to install due to having too many parts, components, or complexity. While there are several remote monitoring systems available, some are easier to install than others, so finding one that allows for quick installation means monitoring will begin sooner rather than later.

Easy User Management

Every fiber monitoring device will include software that allows a user to configure and manage the system on an ongoing basis. Selecting a device with a software interface that is user-friendly and requires minimal to no training results in a quicker setup process. It also allows for a wider range of users to manage the system, not just those with higher levels of technical expertise.

Accurate and Effective Fault Detection

A quality remote monitoring system should include a quality OTDR that quickly and precisely detects fiber faults and issues that arise. If the system can’t accurately locate faults and events, it will not help improve repair times. Additionally, the system should allow for monitoring both dark and lit fibers, as well as point-to-point (P2P) and Passive Optical Network (PON) fibers.

Automatic, Real-Time Alerts

It should go without saying that a remote monitoring solution needs to be able to alert an entity as quickly as possible when something goes wrong. While most systems of today offer this real-time alert capability, the time it takes may vary depending on the monitoring setup configuration - the more fibers a device has to monitor, the longer it will take to switch and cycle through all of them. However, the best systems may only take 2-3 seconds each fiber, so a 16-port system would alert a user in under a minute for an issue on any fiber.

How the system sends alerts is also critical. Many of these systems are SNMP-based devices, and an alert triggers an SNMP trap, which then can be communicated out in that manner or a variety of ways, including:

- SMS / Text

- Integrated mapping tool/application

- Other

The types of alerts are typically dependent on the preferred user setup configuration and the network management servers communicating with the device. Some entities may set up alerts to directly email a repair team, while others may route alarms through their servers or other network management applications.

Quality Technical Support

Because fiber monitoring systems are active devices comprised of both hardware and software, users often have questions when initially installing or configuring the device, as well as periodic questions that may arise later on. Additionally, software should be routinely upgraded as new features and capabilities become available, so it’s important to ensure any system offers comprehensive technical support. Whether answering a simple question or needing to replace a part, it’s beneficial to learn what type of support is available with a device from the manufacturer.

Any Other “Must-Have” Features

While all systems will monitor fibers at the most basic level, are there other must-have features and capabilities that are necessary or would provide a further benefit? For example, does the system need to be integrated with other back-office systems as part of a more comprehensive fiber management system? Is there a popular GIS and mapping tool being used currently that the system should interface with? Are added sensor capabilities, like manhole or moisture sensors, also beneficial to monitor in the network?

Fiber monitoring systems offer an array of different features and capabilities, ranging from basic monitoring and alerting to enterprise-level fiber management capabilities where the monitoring is just one piece of the larger system. It’s always beneficial to think about what is most important or any other must-have features because once a system is selected and installed, it’s not as easy to make a change.

Note: Asking about “coming soon” features and developments is also positive, as perhaps there is a must-have feature that will be ready soon but not currently available. It’s very frustrating to select an alternative system due to perceiving something is not available, only to then find out it is just a month away.

Want to Learn More?

Fiber Optic Monitoring Systems from M2 Optics

If you are interested in learning more about fiber monitoring systems or think you might benefit from installing one in your network, M2 Optics offers a fully-integrated fiber monitoring device and can answer any questions you have about these types of systems.

When you are ready, contact us to get in touch with a fiber monitoring expert.