Fiber optic testing and training are important aspects of ensuring optical communications networks operate successfully as designed and intended. When thinking about the big picture, testing and training happen at many different levels and in a variety of instances both before, during, and after the network has been installed.

Simply put - everything is tested and everyone must be trained at some point, from the equipment itself when it is being designed by a manufacturer, to a service provider architecting and deploying the equipment, and finally maintaining the live network to ensure continued and optimal performance.

While most think about the multitudes of test equipment that is available in the market for engineers and technicians to utilize for all of these tasks, this article discusses a few important ways that spools of bare optical fiber play an important role in a few specialized areas of fiber optic testing.

Key Uses of Optical Fiber Spools for Fiber Optic Testing

There are a few primary applications where utilizing spools of optical fiber are a necessity in the context of fiber optic testing:

- Network and Link Simulation / Emulation

- OTDR Launch Fibers

- Network Engineer and Field Technician Training

All three of these areas are important in the scope of building and maintaining a quality network. In the next sections, we will briefly discuss each in more detail.

Fiber Optic Network Link Simulation / Emulation

With optical fiber serving as the backbone medium for all networks, simulating the physical fiber infrastructure is a must for anyone building or deploying fiber-based equipment. Consider a few of the thought-provoking questions below:

- How does a network equipment manufacturer ensure a new device being designed will perform as intended when a customer deploys it in a live network?

- How can a Telecom service provider determine that a specific network device or type of optical fiber will be the best fit for their existing network when evaluating alternative solutions?

The answer to these questions is simple - utilize spools of optical fiber in the test lab environment to accurately simulate the physical fiber network spans. The only way to truly replicate the performance of an optical fiber and all of its characteristics that is (or will be) deployed in the field is to use matching lengths of that same fiber.

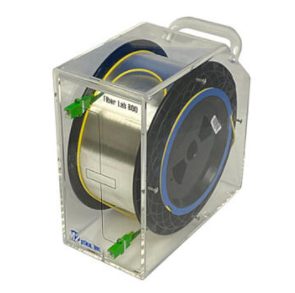

When optical fiber is manufactured and spooled onto reels like in the image below, the fiber itself is in a raw manufactured format, referred to as bare optical fiber. Because it is thin like a human hair (typically 250um in diameter) and not yet in cabled format with all of the protective jacketing, the small diameter allows for significant distances on each reel that are then shipped to cable manufacturers. The vast majority of fiber produced makes its way to cable manufacturers, but a small percentage is used for other applications like the fiber optic testing processes we are discussing.

Since bare optical fiber has very minimal protection (usually a thin 125um layer of coating), it is prone to accidental damage and extra care must always be taken when used for testing and emulation applications. The fiber can be easily broken, crimped, etc. without too much effort when it is being handled. Additionally, the fiber reels themselves are designed and sized to enable effective shipping when they leave the manufacturer facility. However, these physical reels are not always the most space-efficient when used in the test lab environment for these specialized testing applications. This is especially true when a shorter length is being used and when there are simply a lot of spools to use and manage in a lab.

Fortunately, there is a solution to the challenge of acquiring fiber in a more usable and efficient format, which is a professional fiber network simulator/emulator. To support changing needs in terms of fiber types, lengths, connectors, and setup configurations, today’s leading providers will completely customize these platforms to a user’s specifications in a manner that maximizes the value, efficiency, and results of their test fibers. Additionally, they take the hassle out of working with and managing spools of fiber, making tasks easier for the engineer.

OTDR Launch Fibers

Another application in the fiber optic testing arena that requires spools is the practice of using a launch fiber when testing and troubleshooting network cables with an OTDR device. An OTDR, which is short for Optical Time Delay Reflectometer, is a device that is used to characterize an optical fiber and measures values like continuity, total length/distance, signal attenuation, and other important characteristics.

Since an OTDR works by sending an optic pulse signal and analyzing the reflected light, longer pulse widths necessary to achieve longer distances result in something called the “dead zone” at the beginning of the fiber under test, where issues/events are not detected or accurately measured. As a result, an OTDR launch fiber is used to overcome this problem.

An OTDR launch fiber is a short coil or spool of fiber, generally ranging from 100m to 1km, depending on the parameters of the test (ie, shorter for short distance tests, longer for longer distance tests). This fiber spool is placed in-line ahead of the fiber being tested, resulting in a longer total length. By placing more fiber ahead of the actual fiber being tested, the dead zone then occurs in the launch fiber spool thus enabling the OTDR to detect any issues or events at the very beginning of the fiber being tested.

OTDR launch fibers, sometimes also referred to as launch boxes, pulse suppressors, or fiber rings are provided in a variety of compact portable enclosures or module formats that enable a technician to easily carry and use it in the field network along with their OTDR device.

Network Engineer and Field Technician Training

While the first two applications above involved fiber optic testing in the lab and in the field network, spools of fiber are also used in the training environment. Specifically, for training technicians how to use fiber optic testing devices like OTDRs and other gear prior to working in the field.

The way the spools are used is essentially network emulation/simulation again, but addressing a different application goal. While spools of fiber are used for network simulation/emulation in a test lab by those certifying and deploying fiber-based equipment, in this manner, it is to replicate the network environment for training people.

While some training entities may use generic spools of fiber and network components connected together in a makeshift manner (which is not a best practice), professionally manufactured training platforms typically integrate spools of fiber along with other network components like optical splitters, in-line connectors, etc to provide the most realistic network experience in a more efficient manner.

Customized Fiber Optic Testing Solutions

Now that you have learned a bit more about how optical fiber spools are used for everyday testing applications, do you have further questions or require more information?

As the leading provider of customized optical fiber solutions for network simulation testing, OTDR launch fiber, and fiber optic training applications, M2 Optics invites you to contact our team of fiber experts at your convenience. Our vision is to help improve the way fiber is used and managed throughout the globe for advanced communications applications, so how can we support you today?